Complying with relevant standards, the Mattress / Foam Compression Tester is evaluates the degree of firmness common within thepolyurethane foam and furniture industries. The isntrument can be used in research & laboratory, or on the production line. The test adheres to international tetsing stamdards like ASTM D3754. While a Universal testing machine can also be used to conduct the same tests, this is a specialised machine for the test.

This universal measurement of firmness and hardness is based on a physical property called the indentation force deflection (IFD). Which is measured by determining the force required to deflect the test piece a percentage of its original thickness. this is using a circular indentor.

Mattress / Foam Compression Tester Compression Testing

The robust design of Foam Compression Tester includes a circular indentor foot applies a force, while also recording the degree of indentation. To compare test results, test pieces must be of the same size and thickness. The whole article may be used if moulded shapes are being tested.

Mattress / Foam Compression TesterCompression Platen

An apparatus having a flat circular indentor foot 203 mm in diameter connected by means of a swivel joint capable of accommodating the angle of the sample to a forcemeasuring device and mounted in such a manner that the product or specimen can be deflected at a speed of 50 to 500 mm/min. The apparatus shall be arranged to support the specimen on a level horizontal plate which is perforated with approximately 6.5-mm holes on approximately 20-mm centers to allow for rapid escape of air during the test. Special support for contoured molded pads shall be perforated in the same manner as the flat plate unless agreed upon between the supplier and the purchaser. Pads longer than the base plate shall be supported from distortion at the 4.5-N contact force.

Types of platens

- Fixed Platen: the base plate is screwed

- Swivel Platen: the base plate is not fixed and has springs and balls to allow it to level according to the foam sample.

- Spherical Platen: this has a rounded face

Optional Items

IDM-F0013-OP1 - Fixed Platen (8” diameter) ASTM D3574

IDM-F0013-OP2 - Swivel Platen (8” diameter) ASTM D3574

IDM-F0013-OP3 - Fixed Platen (13 ½” diameter) ASTM F1566

IDM-F0013-OP4 - Swivel Platen (13 ½” diameter) ASTM F1566

IDM-F0013-OP5 - Swivel Platen (355mm Diameter) BS EN 1957

IDM-F0013-OP6 - Foam Test Base Plate

IDM-F0013-OP7 - Larger Capacity 5KN

IDM-F0013-OP8 - Swivel Platen - 390 x 390mm - ISO 3386-1

Software to test foam samples

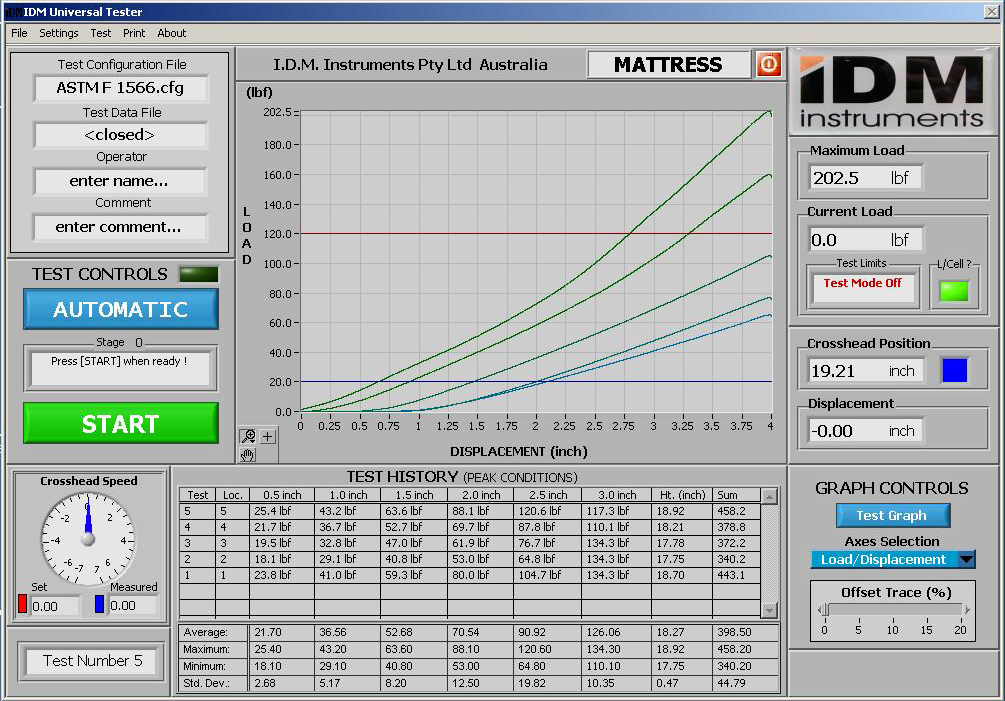

The Foam Compression Tester offers avariety of software features that allows programming of parameters, operational control and real-time display of the on-going test. This software package allows the operator to conduct a wide range of tests with an almost limitless array of test parameters and displayed test information when used with a compatible PC. The PC based control system uses the Universal Tester program developed by IDM Instruments.

The Test Configuration is prepared for each test sample type. This procedure is fully automated. The test scripts, as well as the operating parameters, are entered in the Configuration Panel to run a test. Values including the test type, sample piece, sample size, standard reference and many more values can all be entered and also saved to be retrieved at a later stage. The Software Program for the Foam Compression Tester is automatic. Once the Test Configuration menu has been programmed, “Start” button is pressed, initiating the test. The results of the test are displayed on the PC in real time. They can then be saved and/or printed for later use.

Compression Software Features

- Data Sampling is adjustable from 1-200,000 Hz

- Position or Load control

- Test parameters displayed with graph simultaneously

- Real time graphic display of data

- graphical display presentation

- Data can be sent to Excel

- Out of range stop

- Auto return after a test is selected

- Calibration File to calibrate the instrument

- Statistical analysis

- Printable Reports

- Windows based software

- Overlay display of data curve possible during test

- ISO and ASTM Test Methods programmable

- Other test methods programmable by the operator

- Cyclic testing with data recording during cycle

Foam Compression Indentation force-deflection

Indentation force-deflection is a process used in the flexible foam testing industry to test the "softness" of a foam smaple. These test methods apply to slab, bonded, and molded flexible cellular products known as urethane foams. Urethane foam is generally defined as an expanded cellular product produced by the interaction of active hydrogen compounds, water, and isocyanates. Cellular foam products have been traditionally checked for indentation force deflection by determining the force required to effect a 25 % deflection. In seating, on the other hand, the interest is in determining how thick the padding is under the average person.

When possible, the completed manufactured product shall be used for the test specified. Representative samples of the lot being examined shall be selected at random as required. The ASTM D3754 test method covers determination of the density of uncored foam by calculation from the mass and volume of the specimen. The density value thus obtained applies only to the immediate area from which the specimen has been taken. It does not necessarily relate to the bulk density of the entire molded pad.

The procedure includes placing the test specimen in position on the supporting plate of the apparatus. If the product has one side cored or honey-combed, this face shall rest on the perforated plate. The specimen position shall be such that whenever practicable the indentation will be made at the center of all articles, except where another location is agreed upon by the supplier and the purchaser. Preflex the area to be tested by twice lowering the indentor foot to a total deflection of 75 to 80 % of the full-part thickness at a rate of 250 +/- 25 mm/min. Mark the location of the test area with a pen by circumscribing the indentor foot while under a 4.5-N force. Allow the specimen to rest 6 6 1 min after the preflex. Bring the indentor foot into contact with the specimen and determine the thickness after applying a contact force of 4.5 N (Note 6) to the indentor foot. Indent the specimen at 50 +/-5 mm/min 25 % of this thickness and observe the force in newtons after 60 +/- 3 s. Without removing the specimen increase the deflection to 65 % deflection, allowing the force to drift while maintaining the 65 % deflection, and again observe the force in newtons after 60 +/- 3 seconds.