The Ink Proofer is highly useful for ink manufacturers and printers as an essential quality control tool. Originally, these units were called the 'Peach Proofers'. As the name suggests, the unit comprises of the 'inker' and the 'proofer'.

The 200 x 50 mm prints are useful for colour checking. As well as measurement of density, penetration, set-off and drying. They may also be useful in conjunction with IDM's Ink Rub Testers for rub and abrasion testing.

The Ink Proofer System consists of seperate Inker and printer units. Their design is the result of many years experience in the production of proofing equipment for the in ink industry and is used extensively by both in manufacturers and printers, from small independent to large multinational companies. The Inker is a three roller system, made up of a driving roller, an oscillating roller and a rubber distribution roller which transfers ink to the print disc. The print disc is then transferred to the Printer unit. The material to be printed, which may include paper, card or tin plate is clipped on to substrate carrier and placed on the printing ledge of the Printer. The print disc is then lowered into position and a print produced.

The Inking Unit:

It is a three roller design, consisting of one aluminium drive roller, one aluminium reciprocating roller, and a rubber distribution roller. This roller combination provides quick and uniform distribution of the ink. An arm holds the Print disc in contact with the rubber distribution roller. Thus, giving an even transfer of this ink to the Print disc.

Printer Unit:

Place the inked up print disc from the Inker unit to an arm above a motor driven impression roller on the Printer unit. Then place the substrate to be printed between the impression roller and the print disc on the printing ledge. Apply a printing pressure of up to 1000 N to the Print disc by means of a sliding weight on a graduated bar. Pressing and releasing the print switch provides one revolution of the Print disc.

Options:

|

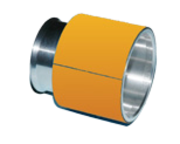

Blanket Print Disc

|

Print Disc with removable blanket. The disc is transferred From the inker to the printer where it is then transferred to the substrate. The Blankets can replaced when worn.

|

|

|

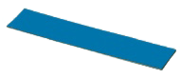

Print Disc Blanket

|

Self adhesive blanket, available for 'UV' and 'conventional' Inks

|

|

|

Solid Print Disc

|

Solid 'PU' Print Disc. The disc is transferred From the inker to the printer where it is then transferred to the substrate.

|

|

|

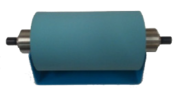

Distribution Roller

|

The distribution roller is where the ink is placed either by volume or weight and is available for 'UV' and 'Conventional' Inks

|

|

|

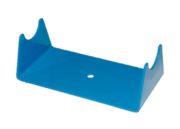

Roller Stand

|

Support stand for the distribution roller to stop distortion of the roller |

|

|

Ink Pipette

|

Measures ink volume up to 1 gram with increments of 1 milligram. The body is made of S/S with a brass inner.

|

|